How the Seed Green came to Omaha

In the 1970s the CLAAS brand was largely unknown in the USA. The LEXION combine harvester was the first machine to make a name for itself in the states, but not in the green and white paintwork. This is because the company had to take a circuitous route though numerous partnerships to break into the highly competitive market.

Matthew Koch had never heard of the name CLAAS when he applied to work for the company in Omaha in 1999. "At that time CLAAS had formed a joint venture with Caterpillar and that was the name that attracted me." The 54-year-old Production Director at the Omaha factory smiles with satisfaction – because unlike then, nowadays the CLAAS brand means something in North America, mainly thanks to him. He grins when he remembers his early days with the company: "Here in the USA, the farmers just called us the 'LEXION guys‘. Although nobody was familiar with the CLAAS brand, they knew about the product. But that's all changed now!“

Omaha is the largest city in the US state of Nebraska in the Midwest. The landscape is impressive – huge fields, one after another, stretching for hundreds of miles, interspersed here and there with small settlements and farms. Anyone driving a pick-up along the seemingly endless roads can see at once why Nebraska is known as 'The Breadbasket': more than 90% of the land here is used for agriculture, making Nebraska one of the most important producers of agricultural products in the USA.

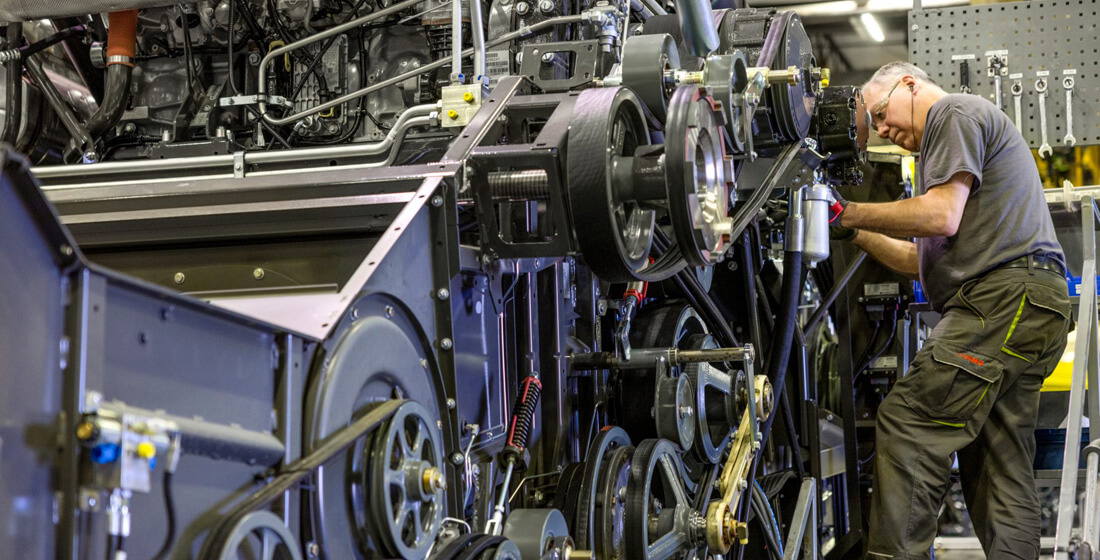

The entrance area of the CLAAS factory in Omaha is surrounded by vast floor-to-ceiling windows, creating a friendly, welcoming impression for visitors entering for the first time. In addition to the 17,000 m2 production building, there is also a prototype workshop for Development, the Quality Management department, a test track and offices. CLAAS Omaha builds more than 600 LEXION 6000, 7000 and 8000 here each year. "We still haven't utilised the full production capacities", explains Matthew Koch. Many more ambitious goals still beckon, as he sees it. Omaha is a success story which he and his colleagues at the site have yet to finish writing.

New machines for large fields

CLAAS can trace its history in the USA back more than 50 years, although the company made its debut on the US market under different names. The first of these was Ford. In 1965 CLAAS signed a partnership agreement with the American company; combine harvesters supplied by Harsewinkel were exported to the USA with the blue-and-white paintwork. The agreement expired in the 1980s, so in 1989 CLAAS joined forces with Massey Ferguson – and the combine harvesters were painted red and sold under another name. Blue-and-white or red, the machines proved popular because they were exactly what the farmers urgently needed, explains Matthew Koch.

The USA is a vast country stretching over several climate zones. The farms and the produce they grow are just as varied as the country itself. While large quantities of rice are grown in California and the south east, the Midwest is known as the maize and soya bean belt. Wheat is grown mainly in the middle, as well as in Canada, along with other types of grain.

Maize is a good example of how arable farming in the USA is different from Germany. As well as being grown on such an enormous area, the planting density for maize in the USA is far greater: around twice as many plants grow on the same area of land. Many are genetically modified and bear more cobs with more kernels per cob.

As a result, there is huge demand for high-performance machines, especially combine harvesters, which can cope with these yields, explains Matthew Koch. "Under very good conditions, you can get yields of up to 27 t per hectare. Cultivation methods in the USA are world-class. Other major growing regions such as Europe or Ukraine achieve only a quarter of that, about 7 t per hectare."

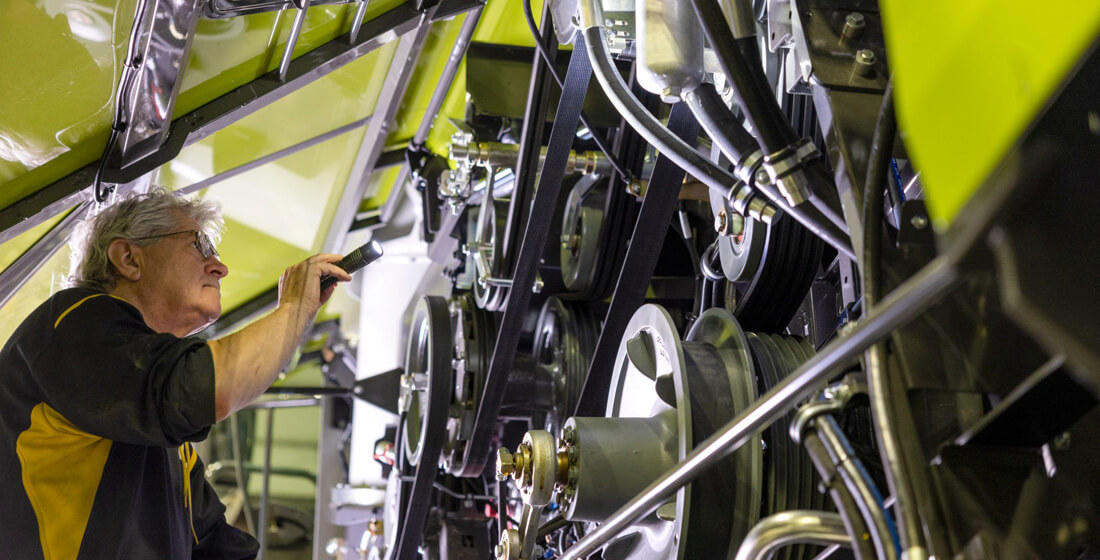

Learning from American farmers

American agriculture needs slightly modified, high-performance machines. And CLAAS itself is benefitting enormously from its involvement in this field, says Matthew Koch. "We get plenty of important feedback and suggestions for improvement from the farmers here. As a result, the combine harvesters are being continually improved. And many of the modifications we make for the American market eventually find their way into German production."

CLAAS Omaha takes feedback very seriously and quickly sets about implementing it so the machines can be modified in time for the next season. It's all systems go in the engineering department in the months after harvesting. The knowledge gained from countless discussions with customers is incorporated into new developments which are then taken up by Production the following year.

Partnerships with local suppliers help to achieve this dynamic pace of change. Although 60% of parts come from other international sites, 40% are produced in close proximity to Omaha. "The development work is a continuous cycle", says Matthew Koch. "Listening to customers, improving the product – and back to the beginning again."

"We want to continue growing in the USA"

Matthias Ristow, Managing Director Business Administration, explains in an interview what's special about the factory in Omaha – and how German and American culture differs.

Interview with Matthias RistowReciprocal visits

It was not combine harvesters, but forage harvesters that planted the name CLAAS in the minds of farmers in the 1980s. "The JAGUAR arrived in America and was so efficient in the field that farmers would have been ill-advised to opt for a different make", reports Matthew Koch. CLAAS became famous almost overnight.

Having its own network of dealerships was a great advantage in this respect. Helmut Claas had personally seen to the establishment of in-house dealerships and partnerships with independent sales partners, initially to bring his balers to market. The JAGUAR was also sold through this dealership network.

The colour of the combine harvesters was to change on a number of occasions over the years. First blue-and-white, then red, they became yellow when CLAAS formed a joint venture with Caterpillar in the 1990s. In fact, this move is what first made Matthew Koch aware of German company. Caterpillar had developed a tractor with crawler tracks, but had no harvesting machines. The deal was that Caterpillar would export crawler tractors to Europe in CLAAS colours and CLAAS in turn would take charge of producing the LEXION combine harvester for North America. The factory in Omaha was built for this purpose. Although Caterpillar stopped manufacturing agricultural machinery in 2000, the LEXION initially retained its yellow colour. It was 2019 before it finally sported Seed Green.

By farmers for farmers

There's plenty of room for growth in Omaha. "We have more than half a square kilometre of land on which we can build and at present we are only using only a very small part of it", says Matthew Koch. "So nothing stands in the way of developing CLAAS of America – we have ample space for new product lines, perhaps even for fabrication, including blanking and painting."

When asked to describe in one sentence what drives him, the production manager doesn't have to stop and think. As the son of farmers, his motivation has much to do with his roots in this region and his childhood on the farm. "Producing high quality machines to help the people I grew up with – that makes me really happy."