It all started with a knot

On 8 April 1913, at the age of 25, August Claas set up his own business. At the family farm in Clarholz, he and his three brothers – Bernhard, Franz and Theo – made straw binders for farmers. Thanks to the superior tying performance of the knotter patented in 1921 and 1923, the firm eventually built up a solid reputation. The knotter became its trademark, and laid the foundations for successful future growth.

CLAAS straw binder from the years around 1900, displayed at the Claas family farm in Heerde. In his father’s smithy, the young August Claas (left) gained a thorough knowledge of the workings and technology of a straw binder.

Without the legendary knotter, the story of CLAAS might have taken a very different course. It all started in Clarholz-Heerde, a small farming community in eastern Westphalia. When the family business operated by his father, Franz Claas Senior, got into financial difficulties, in summer 1913, August Claas, at just 25 years of age, decided to set up a small firm under his own name. The aim of the venture was actually to save the family’s assets, which were at risk of going under the auctioneer’s hammer. On his father’s letterhead, with the “Franz” crossed out and replaced with his “August”, he respectfully informed the competent authority that “since 8 April 1913, I have been running a business in my own name. I employ two fitters and one assistant, and manufacture straw binders. Yours faithfully, August Claas.”

The employees referred to were none other than his three brothers: Bernhard, Franz Junior and Theo Claas. Six months later, they officially became partners in the firm, now trading as “Gebrüder Claas”, or “Claas Brothers” (although it was not until 1940 that Theo, the youngest of the brothers, gained official partner status). The brothers had already gained some experience in making and repairing straw binders in their father’s business, and now continued this work in the new firm. But the four brothers would not have long to get the firm up and running.

In the summer of 1914, the storm clouds darkened across Europe and the rest of the world, and the First World War broke out. The Claas brothers were called up for military service, and the newly established firm had to halt its operations for a time. During their absence, they had no way of preventing the family property in Heerde from being auctioned off on the basis of a farmer’s unpaid account for 85 Mark, and another debt to a joiner for 196.30 Mark. The house and the farm duly passed into the ownership of a coal and timber dealer in Warendorf.

Claas brothers all return home safely

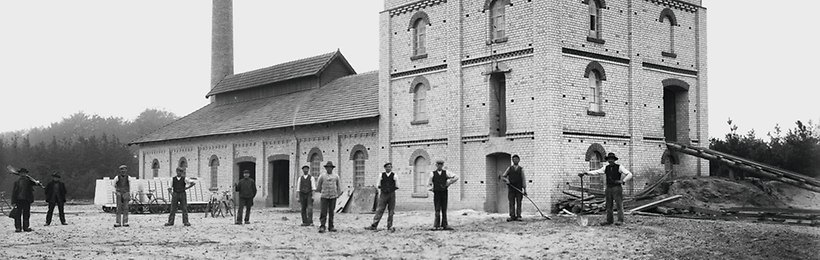

Pioneering years in Harsewinkel. On 7 July 1919, the Claas brothers purchased this disused quarry on Münsterstrasse in Harsewinkel. It was promptly turned into a factory building for producing agricultural machines.

Fortunately, all four sons returned home from the war unscathed. By now, the family had found a new home in the neighbouring village of Harsewinkel. On the outskirts of the village, there was a disused quarry on an area of 1,500 m² – a perfect site for August and his brothers to start the firm up again. The brothers purchased the disused building, which had previously been used to produce chalky sandstone bricks. They paid for the property with the soldier’s pay which they had saved up, and some loans contracted for the purpose.

However, they faced many trials and tribulations on the way to setting up a viable working factory. They had to draw on contacts and acquaintances to acquire the machines they needed: lathes, drills and carpenter’s benches. Step by step, the brothers resurrected the straw binder production operation. As August Claas later recalled: “At first, we couldn’t make any new straw binders, because, in the immediate post-war period, the materials were simply not available. So we bought up secondhand binders that were standing around unused, because there was no twine to be had in Germany. We then overhauled them and sold them on.” From the proceeds from these initial sales of used machines, the brothers were able to buy the timber and metal raw materials they so desperately needed, and also new machinery. The premises of the disused quarry gradually morphed into a hive of industry and activity.

Breakthrough on recognition by the DLG

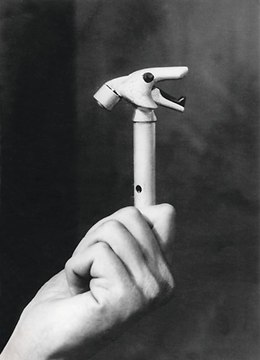

The patented knotter became the firm trademark, under which CLAAS became a familiar name all around the world.

But there was still a problem with these straw binders, which was further exacerbated by the material supply restrictions during the war years. The ever-declining quality of the twine used by the machines was making the tying function of both straw binders and mower binders increasingly unreliable. This resulted in frequent tying malfunctions and machine downtime, a source of major irritation for farmers during the busy harvest period. This led August Claas to take a hard look at the knotter technology. Finally, in 1921, he filed the patent application for his first invention, a knotting device, followed in 1923 by the decisive patent for an “upper lip with restricted pivoting movement”.

In 1924, the German Agricultural Society (DLG) ran a major series of tests on binder-mower machines. Nine German manufacturers took part, including CLAAS with its new knotter. The jury was won over by the technical reliability of the CLAAS knotter. The final report presented by Prof. Dr. Ing. Gustav Fischer of the Technical University in Berlin at DLG’s autumn congress in Würzburg included the following words: “The knotter of CLAAS Brothers in Harsewinkel is superior to all the rest, because it can work with both very thin and very thick binding twine. This knotter is a technical advance of major economic significance.”

Along with its economic benefits for the farmers using it, the CLAAS knotter had a significant positive impact on the company’s business success, thanks to the high demand for the ultra-reliable straw binders available from CLAAS. As the production numbers of straw binders equipped with the CLAAS knotter grew, imports of straw binders from abroad soon started to fall away, and the company actually began to win a major share of the market in those countries as well. The straw binder and knotter became the top seller and trademark of the Harsewinkel firm. It sold its 10,000th straw binder already in 1930. This was the breakthrough that the young company needed, laying the financial foundation for development work on the idea that was to change the European harvesting landscape forever.