Four-rotor swathers

Ingenuity and innovation are the hallmarks of the LINER four-rotor swather. Over 22 years' experience in the market and the field combined with our unshakeable desire for continuous improvement produces outstanding swathing results.

Andreas Wetzel (product manager) and Clemens Frick (design engineer) are a key part of the team responsible for making the LINER four-rotor swather what it is today. Prepare to be won over!

LINER four rotor swather walk around.

Quality forage.

First CLAAS in grass.

LINER 4800 BUSINESS.

United Kingdom.

LINER 4800 TREND.

USA.

DISCO & LINER.

Teamwork.

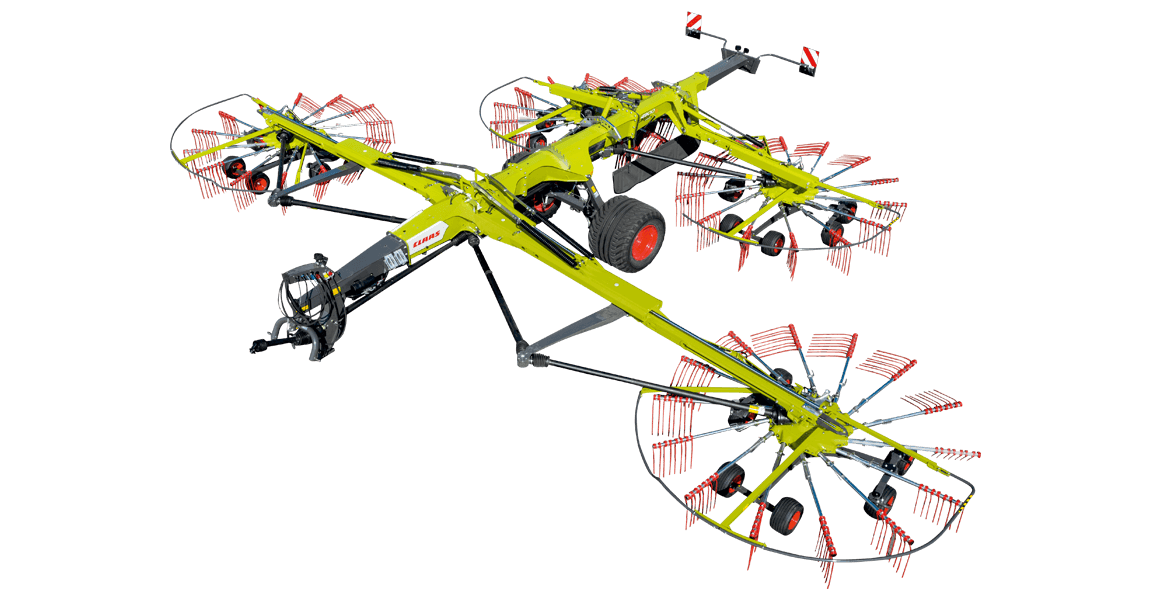

LINER 4900 – 4700

Animation.

Four rotors for a thick swath. With over 20 years' experience.

Invented, tested and refined. The LINER four-rotor swather is synonymous with quality, efficiency, reliability and comfort.

Start configuratorDownload the brochure

Quality.

We understand the importance of doing a first-rate job and producing top-quality forage. So we offer not just the widest tyres on the market, but the largest choice of tyres to boot – not just for the main frame, but for the rotor chassis too. And there's an optional six-wheel version available for all four rotors.

What’s more, CLAAS is the only manufacturer to offer the patented fully floating cardan suspension. A dual spring enables quick and simple equalisation of the rotors to ensure ultra-smooth running – even at higher operating speeds

Efficiency.

Time is money. So we deliberately opted for a mechanical drive because it is simple, direct and efficient. The friction clutches we use provide outstanding power transmission and 'non-stop overload protection'.

In addition, the patented design with double telescopic function and C-profile makes it incredibly easy to switch rapidly between working and transport position – and the working width can be adjusted from the comfort of the cab.

Reliability.

When it comes to the core component of the LINER, we naturally turned to our tried-and-tested rotor drive assembly for professional operators. It runs in an oil bath for continuous lubrication to ensure maximum service life.

The main frame is the primary supporting element in the four-rotor swather, like a spinal column in a human. The enormous cross-section combined with the trapezoidal profile is designed to absorb forces evenly. The control block, electronics module and hydraulic valves are located on the inside, where they are well protected.

Comfort.

If you find yourself doing a night shift, you can still keep a close eye on everything. The six optional LED work lights provide a clear view of main working areas around the machine.

What's more, the machine is not just intelligently engineered – it also features a range of well-conceived solutions designed to make your job easier. For instance, all hose connections are tidily stowed in a special parking bracket. And the hoses are clearly marked to make it easy to attach them.

Quality. For clean forage and a tidy job.

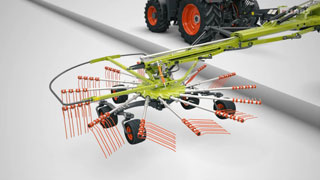

Wide tyres.

In addition to large-volume main frame tyres, the LINER four-rotor swathers can be fitted with the optional six-wheel chassis for all four rotors, which is also available with wide tyres. This increases the foot print by up to 75% compared with the predecessor model.

"The soil is our capital. No other swather currently on the market has such a large contact area, which makes it very gentle on the soil."

Markus Pfender,

operator for Krumm contractors

Quality. For clean forage and a tidy job.

Patented fully floating cardan suspension.

Dual springs on all four rotors ensure perfectly smooth rotational movements. Combined with the suspension, this means that only 20% of the weight is applied to the front tyres of the rotor chassis – enabling optimum ground-contour following by the rotors.

"Patented dual springs steady the rotors at high ground speeds. I am really delighted at how smoothly the LINER moves."

Matthias Buck,

pre-series customer

Efficiency. Thanks to effective, well-conceived solutions.

High-torque drive.

The rotor must be reliable, so we have purposefully chosen a mechanical drive. Numerous tests have shown that this is the most efficient solution – it does a superb job, even handling the enormous quantities of forage you get in the UK, for example.

"Keep going when others have come to a standstill. 50% more power available to the tines than the hydraulic drive."

Raphael Spieler,

LINER test engineer

Efficiency. Thanks to effective, well conceived solutions.

Patented telescopic boom.

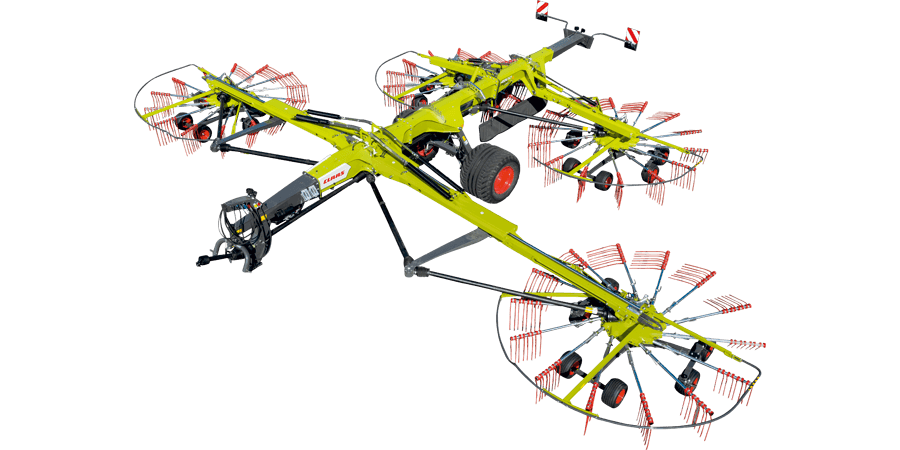

From a working width of up to 15 m to a transport width of just 3 m and a height of less than 4 m – no sooner said than done with the LINER four-rotor swather. It's all down to the unique design of the front arm which features a patented double telescoping function with C-profile. It also allows for rapid adjustment of the working width.

"Despite its 15 m width, it can make itself really narrow. And that's with the tine arms left in place!"

Clemens Frick,

LINER design engineer

Reliability. It's in our machines' DNA.

Continuously lubricated rotor drive assembly.

The core component of the LINER four-rotor swather runs in an oil bath to ensure maximum durability and service life. How do we know this? Because it has stood the test of time a thousand times over.

"The rotor dome assembly runs in an oil bath. This means that the most highly stressed component is continuously lubricated and doesn't require maintenance."

Christine Aßfalg,

CLAAS controller and farmer

Reliability. It's in our machines' DNA.

Sturdy main frame with trapezoidal profile.

The main frame of the LINER four-rotor swather has been throughly shaken around in the run-up to series production as a result of over 20,000 ha of operational experience and countless hours on the test bed. And the result? Passed with flying colours!

"The large frame with trapezoidal profile is as tough as they come. It's incredibly robust and solidly constructed."

Uli Biesenberger,

CLAAS test bed engineer

Comfort. Making life that little bit easier.

Hoses clearly assigned to couplings.

Whether you choose the BUSINESS or TREND version, the cleverly designed hose cabinet not only keeps the hoses clean and tidy; marking the function on both the hose and the corresponding connector makes for very simple attachment and removal.

"No one wants to waste any time on the field. The hoses are clearly marked and attaching them is child's play."

Linus Kesenheimer,

LINER design engineer

Comfort. Making life that little bit easier.

LED work lights.

Sometimes night falls before your working day is over. But you still need a clear view of the rotors and the work area – now you have it, with six perfectly positioned optional LED work lights.

"You can only work well if you can see well. LED headlights illuminate the work area as bright as day."

Michael Wessner,

LINER assembly supervisor and contract operator

The ultimate in professional equipment – the four-rotor swather.

Flexible U-frame hitch.

All LINER four-rotor swathers have a robust 2-point hitch with a maximum steering lock of up to 80° and ample space to accommodate lateral movement of up to 20°. When the machine is unhitched, the drive shaft can be conveniently stowed in the handy shaft holder.

Semi-automatic parking stand.

All LINER four-rotor swathers have a cleverly designed semi-automatic stand which can easily be operated with just one hand.

Parking brackets.

All models, whether BUSINESS or TREND, feature the convenient parking bracket. Designed to keep all connections neatly stowed and make light work of connecting the machine.

Unbeatable ground-contour following.

The sophisticated interaction between the rotor chassis, cardan suspension and dual springs ensures impressive agility with remarkably smooth rotor guidance – even when travelling at the highest speeds.

Tyre types

800/35-22.5

- Maximum soil protection

- Excellent driving comfort

710/45 R22.5

- Safe deployment on slopes

- Maximum soil protection

600/50 R22.5

- Safe deployment on slopes

- 1.17 m diameter for large contact area

500/55-20

- 1.05 m diameter

| 4900 BUSINESS | 4800 BUSINESS | 4800 TREND | 4700 TREND | |

|---|---|---|---|---|

| Rotor chassis | ||||

| 16 x 6.50-8 | ● 4 x 4 (○ 4 x 6) |

● 4 x 4 (○ 4 x 6) |

● 4 x 4 (○ 4 x 6) |

● 4 x 4 (○ 4 x 6) |

| 16 x 9.50-8 | ○ 4 x 4 / ○ 4 x 6 |

○ 4 x 4 / ○ 4 x 6 |

○ 4 x 4 / ○ 4 x 6 |

– |

| Main frame | ||||

| 500/55-20 | (○) | ● | ● | ● |

| 600/50 R22.5 | ● | ○ | ○ | ○ |

| 710/45 R22.5 | ○ | ○ | ○ | ○ |

| 800/35-22.5 | ○ | ○ | ○ | – |

More milk per hectare.

The wide tyres on the main frame and rotor chassis increase the footprint by up to 75% to protect the soil, reduce the crude ash content and deliver premium quality forage.

Mechanical drive with friction clutch.

- 50% more power to the tines compared with the hydraulic drive

- Torque-friendly power transmission

- Non-stop overload protection

- Moves more forage

BUSINESS and TREND equipment options.

ISOBUS control.

Flexible operation in the field.

Well-thought-out operation.

Turns night into day.

ISOBUS control.

These models are equipped with ISOBUS and numerous automation functions designed to lighten the operator's load. A wide variety of machine parameters can be individually configured, saved and adapted to the field conditions with just one click.

Flexible operation in the field.

Individual rotor lift allows the operator to control each rotor separately in response to varying field conditions and shapes. In the automatic lift and lower mode, the operator can choose between time- and route-dependence. If necessary, this function can be manually overriden by holding down the key.

Well-thought-out operation.

The machine can be operated with the CEMIS 100 machine terminal or by ISOBUS via the CEMIS 700 or any other ISOBUS-enabled terminal via AUX-N or AUX-O. The ability to assign various functions to the spool valves and function keys of the tractor makes operating the machine exceptionally straightforward. In automatic mode, the working and swath width as well as the folding and unfolding function can be adjusted continuously. If the LINER is equipped with hydraulic rake height adjustment, positions can be saved and controlled individually.

Turns night into day.

All LINER BUSINESS four-rotor swathers can be fitted with six LED work lights as an option. They are carefully positioned to illuminate all four rotor work areas along with the swath and the surrounding area to give the operator the clearest of views.

Direct operation with spool valves.

Working width and swath width adjustment.

Direct operation with spool valves.

If you opt for this machine, you benefit from simple, direct operation via spool valves. Furthermore, this model needs only two double-acting spool valves for the front arms and the main frame and telescopic arm. A single-acting spool valve is additionally required to control the rear rotors. With optional sequential control, this spool valved is not needed. Alternatively, you can choose the PLUS control option and take advantage of the individual lift function for the front rotors and more convenient folding via the CEMIS 10 terminal.

Working width and swath width adjustment.

The working width can be continuously adjusted from the cab. The swath width can be adjusted in transport position without tools using a hole matrix.

The Big Four. You can count on us.

LINER 4900

BUSINESS

- Working width: 10.10 – 15.00 m

- Rotor diameter: 3.80 m

- Tine arms per rotor: 14

- PROFIX: as standard

LINER 4800

BUSINESS/TREND

- Working width: 9.30 m – 13.60 m

- Rotor diameter: 3.50 m

- Tine arms per rotor: 12

- PROFIX: as standard

LINER 4700

TREND

- Working width: 9.30 – 12.70 m

- Rotor diameter: 3.30 m

- Tine arms per rotor: 12

- PROFIX: as standard

Experience the LINER with augmented reality.

Wondering how the new LINER will look on your farm? Just click the button to open an augmented reality application which puts a 3D rendering of the machine in your yard. You can use your smartphone to view it from all sides and take a close look at all the details.