Technology.

MAX SPREAD.

Wider crop uptake, thanks to a more efficient crop flow system.

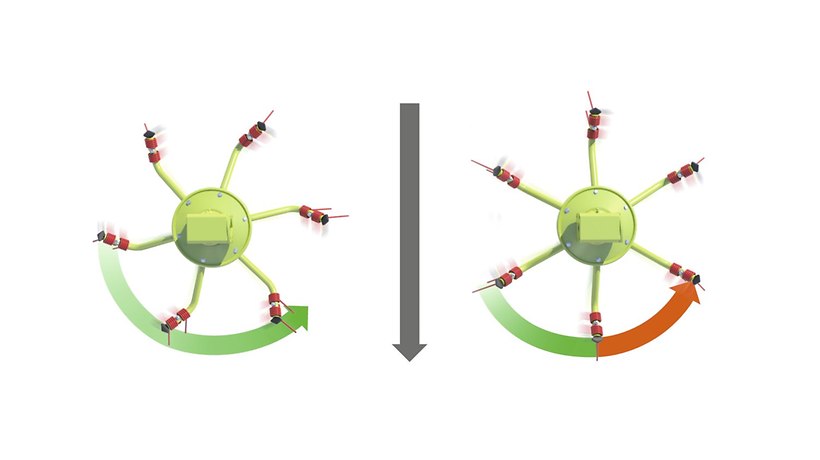

Thanks to the trailed tine connection in the MAX SPREAD crop flow concept, the tines are always positioned in or crosswise to the direction of travel as the crop is taken up. In conventional designs, the tines operate opposed to the direction of travel after just half of the pick-up area, thus limiting the forward speed. In the MAX SPREAD crop flow system, the tines operate for 33 percent longer in or crosswise to the direction of travel. So MAX SPREAD enables you to work significantly faster, or with a lower engine speed.

Straight-line crop flow for gentler transfer.

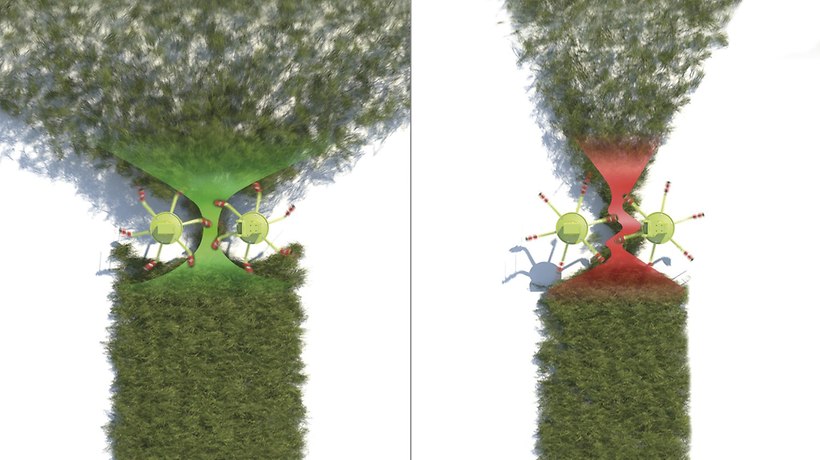

Since the tines are always positioned at right angles to the crop during pick-up, they can deflect to the rear in the direction of the tine winding. This offers the advantage over conventional systems that the crop flow between the rotors is almost perfectly linear. This creates more space for the crop transfer, and ensures enhanced throughput and exceptionally gentle handling of the forage. The MAX SPREAD concept therefore also allows the tedding of leafy crop types such as alfalfa at reduced engine speeds.

More uniform distribution, thanks to the tine connection angled to the rear.

The 29.3° trailed connection also has a positive impact on crop delivery. In the same way as the trailed spreading blades of a fertilizer spreader, this configuration ensures a wider and more even distribution of the harvested crop, for an optimal spread pattern. This fertilizer spreader effect is further supported by tine tension release in the direction of the winding, to spread the crop over the entire width.

MAX SPREAD – experience in the field.

Multi-Agrar Claussnitz GmbH in Claussnitz in central Saxony manages a total of 3,100 hectares of grassland, and for 20 years has relied on CLAAS products when forage harvesting. Among other products, the company uses a VOLTO 1100 T, which is fitted with the MAX SPREAD crop flow concept.

Employee Michael Polster places particular emphasis on silage quality: "Dairy cattle are the biggest segment of our business. We have a total of 1,400 cows, with an average milk output per cow of 10,000 kilograms annually. That means the quality of our forage needs to be perfect."

"The VOLTO 1100 is a highly successful machine in every respect. We have been particularly impressed with the spreading pattern, which remains tidy and consistent in tough agricultural grasses, and when processing large forage volumes. Even at higher working speeds, the material is spread across the full width of the machine. We are completely satisfied with the VOLTO 1100, as a machine that helps us achieve outstanding forage quality."

Higher productivity, thanks to optimised crop flow.

With the MAX SPREAD crop flow concept, CLAAS has fundamentally improved the operational quality of the tedding process. Through the 29.3° trailed connection of the tines, the crop flow has been efficiently optimised in several respects, delivering the following benefits:

- Enhanced spread pattern

- Higher working speeds

- Gentle forage handling

MAX SPREAD – convincing the experts.

"None of the panel would have guessed that there was still scope for this level of innovation in such a technically mature process as tedding. The MAX SPREAD crop flow concept has been a hit with the judges and has duly been awarded the ZLF Innovation Prize."

Norbert Bleisteiner, judges' spokesperson

User-friendly detailed features.

Better control – through reliability.

CLAAS power flow drawbar for smooth and safe movement over the ground.

For comfortable and efficient operation, all three-point hitched machines are fitted with the CLAAS CKL power flow drawbar. This ensures smooth trailing around curves, and reliably prevents overrun on slopes. Automatic centring during lifting transfers the weight to the tractor lower link. As well as relieving the strain on the chassis and immobilising the machine, this also brings the centre of gravity close to the tractor.

Good directional control at any speed.

Extra-wide balloon tyres ensure reliable ground-contour following, optimal soil protection and smooth running, even at high working speeds. The tyres are protected against undesirable crop build-up.

Adjusting to the situation: the optional guide wheel.

Optimised ground-contour following independent of the tractor movement is particularly important in hilly terrain. With the optional additional castor guide wheel, the VOLTO is guided smoothly over the ground, and the work height can be set without the use of tools. This stops the tines from digging into the grass cover, and prevents forage soiling.

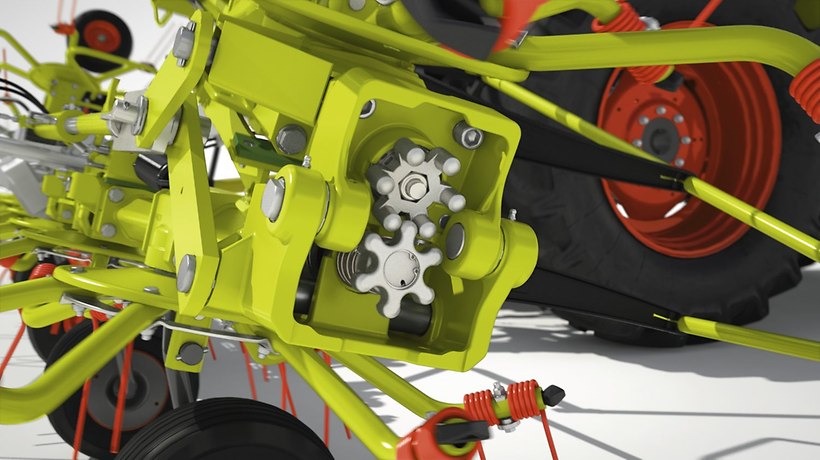

Patented power transmission: the PERMALINK finger clutch.

Power transfer on the VOLTO machines is via the patented PERMALINK finger clutch. The unit is entirely maintenance-free, and ensures a reliable transfer of power in all operational conditions. What's more, the innovative new design enables folding movements of up to 180°, allowing retraction to a compact transport position.

An easier tedding operation with robust spreader arms.

The highest forces acting during tedding are exerted on the spreader arms. They are therefore made from rounded tubing for high torsion resistance, bolted to the rotor plate, and further stabilised with a support ring with recesses.

Depending on the model, the VOLTO has a rotor diameter of 1.30, 1.50 or 1.70 metres, with five, six or seven spreader arms, respectively.

Robust, securely attached tines.

All VOLTO hay tedders are fitted with strong, robust tines. Dual tines with five windings each are fitted on the tine arm and secured with a bolt. In the event of a breakage, the tine-loss protection system reliably prevents any risk of tines flying off and causing damage.