TERRA TRAC on JAGUAR.

Building on the well-recognised advantages of the TERRA TRAC crawler tracks with regard to soil protection and traction, CLAAS is the first forage harvester manufacturer to launch an optimal factory-integrated solution for the protection of soil and grassland against driving damage: the newly developed JAGUAR TERRA TRAC with headland protection. A notable innovation of this machine is the headland protection feature which reduces the track contact area at the headland, thereby protecting the grass cover. The JAGUAR TERRA TRAC is currently undergoing extensive field trials. When launched, it will make it possible for the first time to use the advantages of a crawler track system on a forage harvester on all surfaces throughout the whole year:

- Year-round operation without modification allows a high degree of machine utilisation

- Headland protection through automatic reduction of the track contact area when cornering or turning (less scrubbing)

- Fast transfers within a 3 m transport width (635 mm track) at up to 40 km/h

- Operating reliability under difficult conditions with high traction and low rut formation

- Long service life of new type of track with large number of ribs

Low rut formation improves accessibility for all the other vehicles in the crop handling chain

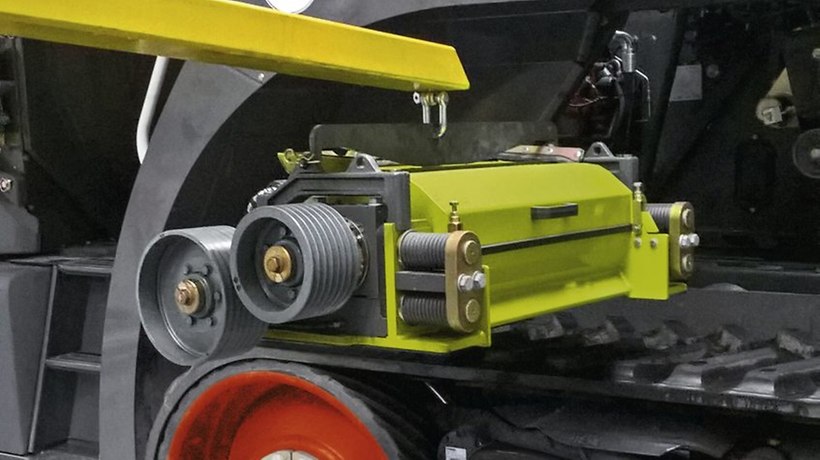

Headland protection: track contact area is shortened automatically by lifting the land wheels when cornering

Good accessibility: possible to remove corncracker from the side above the crawler track

With the 635 mm wide track, the JAGUAR has an external width of 2.99 m

JAGUAR TERRA TRAC – the first test.

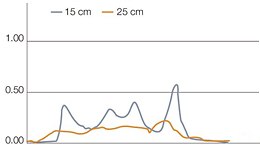

Studies conducted by Kiel University of Applied Sciences confirm the positive effects of the measures to protect the soil and, in particular, the headland. During straight-ahead running, the JAGUAR equipped with the TERRA TRAC crawler track system exerted a load on the soil that was significantly lower than that of a wheeled machine with 800/70 R 38 front tyres and 620/70 R 30 tyres at the rear.

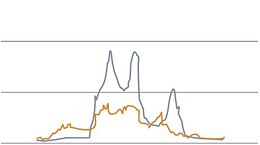

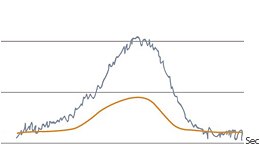

Compaction studies were also carried out at the headland. It was suspected that the soil pressure of the crawler track machine in headland mode would increase because of the shortening of the contact area. However, even with the 635 mm wide track, the results clearly told a different story: despite the active headland mode, the soil pressure load figures were approximately the same as those for a wheeled machine.

Soil compaction was not the only effect that was analysed. Damage to the grass cover and subsequent crop growth were also investigated. This involved conducting assessments of the growth height, rut depth and damage to the grass cover. The result: the figures attained by the JAGUAR TERRA TRAC with headland protection when turning with a reduced track contact area and narrower rear tyres practically matched those of the wheeled machine and confirmed that it protected the grass cover.

Headland protection, along with the many other advantages of the drive concept, such as soil protection, increased traction and a transport width of less than 3.0 m (635 mm tracks), proved itself in the study and demonstrated improved overall performance compared with conventional wheeled machines.

- Soil pressure measurements obtained with the three variants: Wheeled machine during straight-ahead travel, TERRA TRAC machines during straight-ahead travel and cornering.

Source: Kiel University of Applied Sciences, Prof. Reckleben (2017)

- Soil pressure measurement during cornering.

TERRA TRAC without headland protection

TERRA TRAC with headland protection

Wheeled machine

The TERRA TRAC crawler track system causes significantly lower soil pressure than the wheeled machine, even in headland mode. Source: Kiel University of Applied Sciences, Prof. Reckleben (2017)